By Clint Thompson

The secret to Florida blueberry growers’ future success may rest with the advancement of mechanical harvesters. Especially as producers try to compete with rising imports amid the disparity between labor wages, farmers need the advantage of not having to depend on H-2A workers to harvest their crops.

Doug Phillips, University of Florida (UF) Institute of Food and Agricultural Sciences (IFAS) Blueberry Extension Coordinator, said mechanical harvesters are in the early phases of adoption on a commercial scale.

“I think to be successful, a lot of the growers are going to be adopting it. They realize where their most significant costs are, where the big cost differentials are,” Phillips said. “But to just be competitive in pricing, I think a lot of folks realize they need to start heading in that direction.”

Labor’s Costly Expense

According to Jeff Williamson, professor in the horticultural sciences department at UF/IFAS, hand harvesting is the costliest expense for growers. Berries are normally picked every 2 to 4 days. Labor supply can also limit harvest-time operations.

That places an emphasis on adaptation of mechanical harvesters. Growers can not survive long-term especially when competing against rising imports from Mexico.

Refinements Needed

Mechanical harvesters and blueberry breeding also need to be refined so fruit damage does not occur. It is currently a common problem.

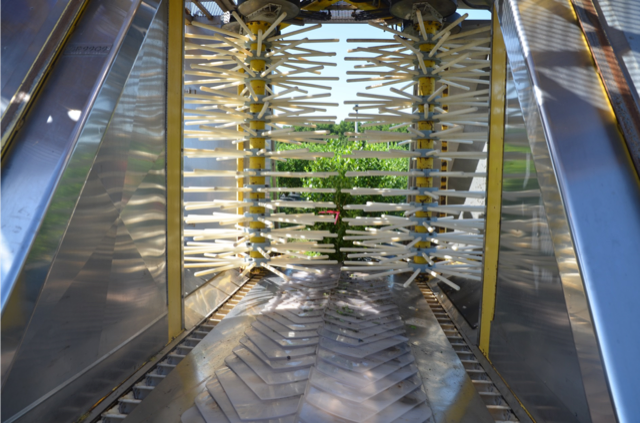

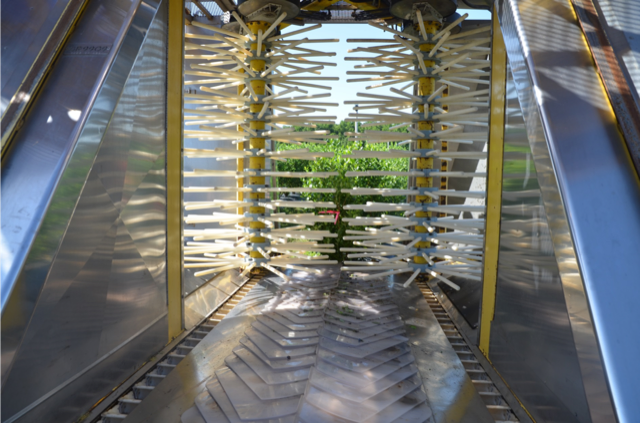

“There’s some characteristics you’d really like to see for something that will machine harvest really well. Part of that is fruit firmness. When you think about it, you’ve got this machine that comes through and shakes the bush with these fingers. The berries fall on the catch plate. That’s where some bruising can take place,” Phillips said. “You want a variety that’s got firm berries, and you want something that’s got decent detachment force where you’re shaken free the blue fruit and not the green fruit. You want something that’s got a narrow base of the plant so that these scales at the bottom that close around the plant fit well around the plant so you’re not losing a lot of fruit onto the ground as it’s being shaken.”

He said this is a focus of UF and its breeding program.

“Part of it is it’s the breeding program and making sure they concentrate on firm fruit, which they very much are. Part of it’s technology where they’re finding softer catch plate surfaces that are less likely to do that bruising when the fruit falls. I think it’s both a breeding genetics target and improving the technology,” Phillips added.

Florida’s market share in blueberries was 2.7% compared to Mexico’s 18% in 2020, according to a recent report from the Florida Department of Agriculture and Consumer Services. Florida’s blueberry sales decreased by 16.1% from 2012 to 2020. Florida produced 22 million pounds in 2020, compared to Mexican imports that netted 112 million pounds.