By A.S. Culpepper

Vegetable growers continue to face a tremendous number of production challenges; fumigation is no exception. With the loss of methyl bromide and Paladin, current sustainable systems for producing multiple crops on a single mulch installation often include finding the optimum combination of 1,3-dichloropropene (Telone II), chloropicrin and/or metam sodium (Vapam, Sectagon, etc.).

However, fumigant selection is only one part of the battle, as selecting the ideal mulch to accompany the fumigant system allows one to optimize pest management while managing plant-back intervals. As if fumigant and mulch selection are not complex enough, it is likely that the most sustainable growers will also master the understanding of how soil texture, soil moisture, bed compaction and soil temperature all influence the program’s success. Steps to consider when developing a fumigation system include the following:

STEP 1: REDUCE FUMIGANT SYSTEM COSTS BY BATTLING NUTSEDGE YEAR-ROUND

The late Ted Webster, U.S. Department of Agriculture research agronomist, once showed that a single purple nutsedge tuber growing in plasticulture could expand to a patch size exceeding 66 ft2 with 3,440 shoots in 60 weeks. This research tells us that if we achieve 99 percent control of purple nutsedge with each fumigation cycle (assuming one shank fumigation every 15 or more months), then nutsedge will actually prosper.

If 99 percent control with fumigation isn’t good enough, how do we manage the No. 1 weedy pest in plasticulture vegetable production? The best answer currently is year-round nutsedge management to eliminate tubers from being added to the soil seed bank. Over time, this war on nutsedge will bring costs down as fields heavily infested with nutsedge require higher fumigant rates, additional fumigants/herbicides and more expensive mulches when compared to fields with no or low levels of nutsedge. Here are a few ideas to get started:

1) Nutsedge should be eliminated from row middles; Sandea herbicide is labeled for many crops.

2) Terminate weeds as soon as harvest is complete.

3) Rotate a full rate of Roundup with disking on three-week intervals when crops and mulch are not present (tuber production can occur within three weeks of emergence).

4) Rotate Roundup and Gramoxone when the crop is not present but mulch is present. Remember to make sure mulch is washed prior to planting.

STEP 2: PREPARE FIELDS FOR THE IDEAL FUMIGATION AND BED FORMATION

Fields should be free of debris and clods with moisture ideal for forming the perfect bed as shown in Figure 1. Deep turning the land prior to fumigation will improve control of numerous pests, especially small seeded weeds. Bed compaction varies by soil type, but for most fields a good rule of thumb is for a 150-pound person to sink about half an inch when stepping on the bed. This will facilitate ideal fumigant, water and fertilizer movement.

Common mistakes often include 1) fumigating when soils are too dry (shoulders fall apart), allowing the fumigant to escape and 2) applying Telone II when it is too wet, trapping the fumigant in the bed and potentially damaging the crop at planting.

STEP 3: SELECT FUMIGANT AND MULCH

Two broadcast rate options for Georgia are as follows:

Option 1: Telone II at 12+ gallons per acre (GPA), chloropicrin at 150 pounds per acre and metam sodium at 75 GPA. Telone II is typically applied 14 to 18 inches deep followed by chloropicrin injected 8 to 10 inches deep with three knives in a typical 32-inch-wide bed top. Place metam in the final bed with injection points 4 inches below the final bed top and 4 inches apart (Figure 2). Pic-Chlor 60 can successfully replace Telone II and chloropicrin in fields with low nematode levels.

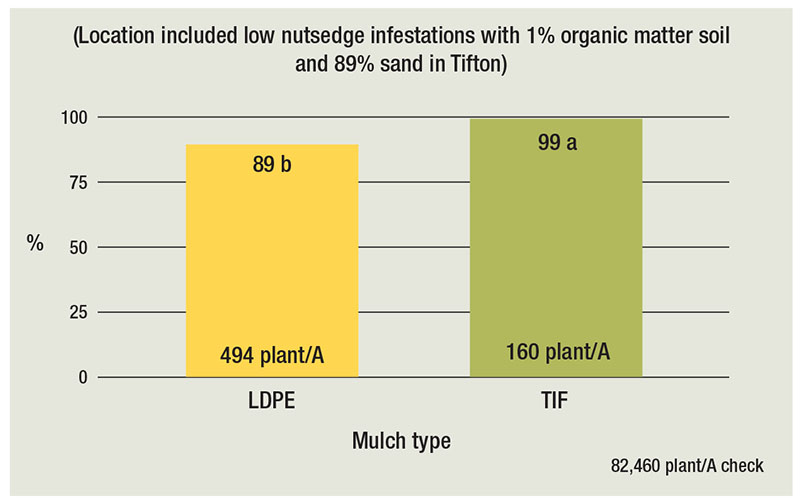

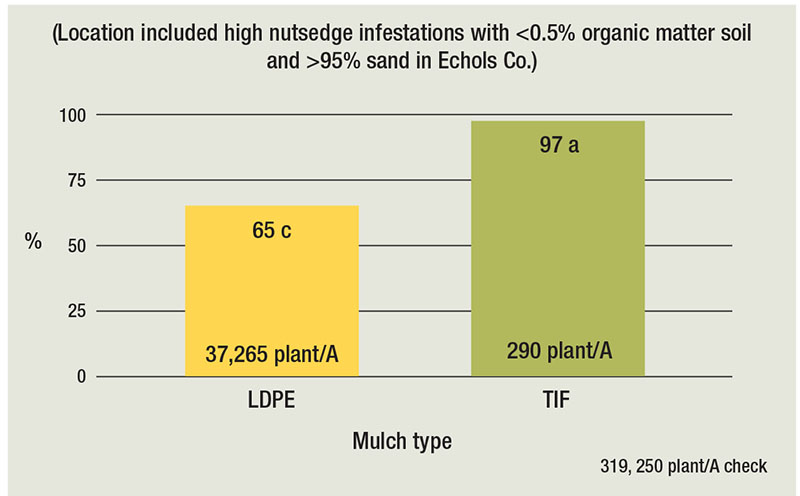

Selecting the ideal mulch for this system is critical. In areas with heavy nutsedge infestations, very sandy low organic soils or during challenging conditions, a totally impermeable film (TIF) may prove to be more effective than the standard low-density polyethylene (LDPE) mulch (Figure 3 and Figure 4). Plant-back intervals can be twice as long with TIF mulch, so plan accordingly.

Option 2: Pic-Chlor 60 applied under TIF at 28 GPA (340 pounds per acre) can be an effective option, especially when 1) producing only one or two crops prior to mulch removal, 2) applying in fields containing light nutsedge and nematode infestations and 3) when growing crops that allow topical Sandea applications.

STEP 4: DETERMINE IF HERBICIDE IS NEEDED

Under mulch: If metam and chloropicrin are applied in a system, then an herbicide is usually not needed; herbicides would likely benefit other programs.

Row middles: An herbicide program is needed for nearly every field. Most weeds build up populations as a result of row-middle weed escapes, especially purslane, grass and pigweed.

Topical applications: Applications are encouraged where herbicides are available (without injury risks) as a means to mitigate weed competition and seed production.

Herbicide selection: Herbicide labels vary greatly by state, so contact your local Extension office for the latest tools.

Follow all federal and state pesticide label requirements. Also, follow the fumigant management plan and fit-testing requirements for chloropicrin and metam.